http://nomadletterpress.com/services/monotype

Nomad Letterpress

Whittington Press

nr Cheltenham

Gloucestershire

GL54 4HF

Nomad Letterpress was established by Pat Randle in 2011 in order to specialise in limited edition, fine press book work whilst harnessing the enormous creative potential of printing from lead and wood type. They are dedicated to continuing a tradition of fine letterpress printing, exemplified both by the high quality of work carried out for clients and in the training of a new generation of letterpress printers.

Near my home town:

The fact that Nomad are conscious of a 'new generation' of letterpress printers could provide a potential location to broaden my skills and technical knowledge on letterpress printing. The studios description and rationale is complimentary of my practice because they want to see realise the potential of traditional print methods in the digital age. It is encouraging to find studios that share the same objectives and aims.

Printing presses:

Fag Swiss Proof 40 (maximum sheet size: 405 x 580mm)

Fag Swiss Proof 52 (520 x 720mm)

Western A-Bed (20″ x 28″)

Heidelberg Platen (10″ x 15″)

Heidelberg Cylinder SBB (photo, 22″ x 30″)

Farley (12″ x 18″)

Albion (14″ x 18″)

Fag Swiss Proof 40 (maximum sheet size: 405 x 580mm)

Fag Swiss Proof 52 (520 x 720mm)

Western A-Bed (20″ x 28″)

Heidelberg Platen (10″ x 15″)

Heidelberg Cylinder SBB (photo, 22″ x 30″)

Farley (12″ x 18″)

Albion (14″ x 18″)

I lack experience with this equipment therefore it would be a really beneficial if I gain some practical experience before contacting the studio for a work placement. Neil Winter currently operates the three Monotype composition casters. Clearly a very technical job where experience is key to being successful:

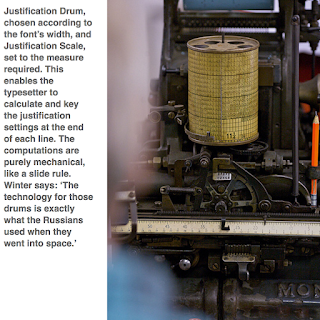

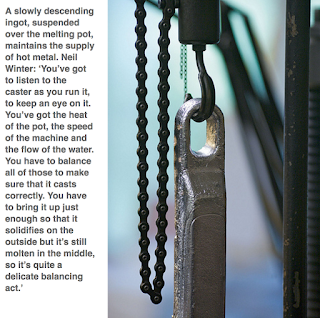

'The accuracy with which type is cast is critical in giving the right flavour to any work; squareness of type body, alignment of face, clarity of casting, closeness and regularity of word spacing, correct hyphenation are a few of the requirements the Monotype operator needs to coax from a machine of immense complexity and subtlety, achieved in part by the correct balance of machine speed, metal temperature, water cooling and compressed air supply. Once a job has been completed the type goes back in to the melting pot and the process of recasting begins, meaning that we are always printing from freshly cast type.'

Eye Magazine have recognised Winter's efforts in keeping the tradition alive:

http://www.eyemagazine.com/feature/article/machine-and-man

It made me even more aware of the technical process and the important role that Neil Winter plays:

I am really interested in the physical process of creating type from scratch and the fact that the type can be melted back down a recast makes it an ever evolving process. There is definitely more to typesetting than I previously envisioned. I prefer to work manually because it allows me to gain a better understanding of the process so learning these skills will also benefit me when typesetting digitally.

Letterpress Jargon:

Researched into some of the jargon associated with letterpress so that I can gain technical vocabulary:

Reglet: A thin strip of wood or metal used to separate type.

Ingot: A block of steel, gold, silver, or other metal, typically oblong in shape. This is slowly melted down and poured into the text caster.

Ligature: Two or more letters are joined together to form one glyph or character. Definition: Two or more letters combined into one character make a ligature. In typography some ligatures represent specific sounds or words such as the AE or æ diphthong ligature.

The fact that they're looking for a new generation of letterpress printers is encouraging because it provides potential for me to get in contact with Nomad and see if they have any schemes or workshops that I can attend to get involved.

Whittington Press

Alongside Nomad Letterpress is The Whittington Press which Neil Winter also works for. The presses share the same location. Winter was involved in the production of Double Dagger, where he cast the type through a Monotype composition caster and printed the letterpress through a Heidelberg Cylinder.

Double Dagger explores established designers views and opinions on what excites them about printing with hot metal type. Winter has printed the entire 12 page broadsheet using traditional letterpress which celebrates the old medium in a contemporary context.

Getting in contact with Double Dagger and asking them about the project and working with a letterpress studio will be really beneficial and I will gain some more contacts.

The Studio has an open day where anyone and everyone can visit the studio, take a look around and browse through stalls of printed materials. The event is on the first weekend on September every year and the fact that it isn't too far away from me means that I am likely to attend.

No comments:

Post a Comment